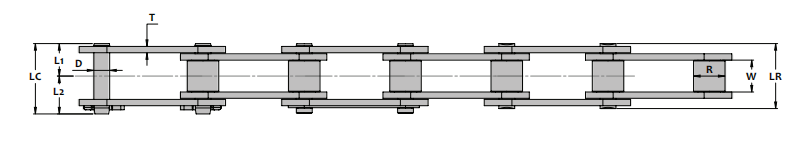

Double Pitch roller chains are created in accordance with all the ASME/ANSI B29.three (Transmission Series) and B29.four (Conveyor Series) American roller chain specifications. Usually these chains are very similar to ASME/ANSI regular items except that the pitch is double. They are readily available in Transmission Series, Conveyor Series with Conventional (little) Rollers and Conveyor Series with Substantial (oversized) Rollers.

Transmission Series

This series is usually used on drives with slow to moderate speeds, lower chain loads and long center distances. Side plates have a fi gure ?¡ã8?¡À contour. The chain quantity is obtained by adding 2000 to the ASME/ANSI chain  quantity as well as prefi x letter ?¡ãA?¡À. Note that some organizations never use a prefi x letter for this series so the chains could be represented as A2040, A2050 and so forth. or 2040, 2050 etc.

quantity as well as prefi x letter ?¡ãA?¡À. Note that some organizations never use a prefi x letter for this series so the chains could be represented as A2040, A2050 and so forth. or 2040, 2050 etc.

Conveyor Series with Typical (compact) Rollers

This series is usually utilized on light to reasonable load material handling conveyors with or with out attachment hyperlinks. The side plate contour is straight for improved sliding properties. Pitch sizes of 1-1/2?¡À and bigger have ?¡ãHeavy?¡À series website link plates (i.e. link plates from the subsequent bigger chain dimension. The chain variety is identified by including 2000 to the ASME/ANSI chain number along with the prefi x letter ?¡ãC?¡À. Chains with all the ?¡ãheavy?¡À sort side plates use a suffi x letter ?¡ãH?¡À.

Conveyor Series with Large (oversized) Rollers

These chains possess significant rollers to ensure the chain rolls on the conveyor track reducing friction. Chain numbers are observed during the same way as noted over except the last digit over the chain number is transformed from ?¡ã0?¡À to ?¡ã2?¡À which denotes the huge roller.

Sprockets

Usually sprockets must be made specially for these chains according to your ASME/ANSI B29.3 and B29.4 specifications nevertheless, for Transmission Series and Conveyor Series with Normal (small) Rollers, ASME/ANSI B29.1 Typical roller chain sprockets may well be utilized supplied the quantity of teeth is 30 or far more.