Product Description

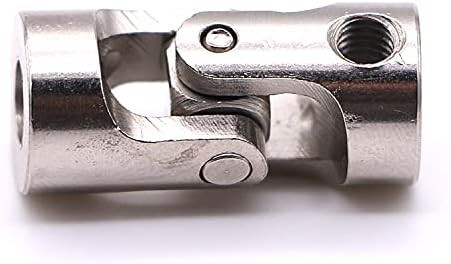

HangZhou XIHU (WEST LAKE) DIS. custom made cardan shaft /U joint shaft for rolling mill

Brief Introduction

Processing flow

Applications

Quality Control

Product Description

| structure | universal | Flexible or Rigid | Rigid | Standard or Nonstandard | Nonstandard |

| Material | Alloy steel | Brand name | HangZhou XIHU (WEST LAKE) DIS. | Place of origin | ZheJiang ,China |

| Model | SWC225-250A-1400+600 | Raw materials | Castings/Forgings | Length | 1400mm+600mm |

| Flange DIA | 225(250)mm | Nominal torque | 40Kn | coating | heavy duty industrial paint |

| Paint clour | customization | Application | equipments | OEM/ODM | Available |

| Certification | ISO,TUV,SGS | Price | calculate according to model | Custom service | Available |

Packaging & Delivery

Packaging details:Standard plywood case

Delivery detail: 15 -20 working days,depend on the actual produce condition

FAQ

Q1: What is the location of your company?

A1: Our company is located in the HangZhou City ,ZheJiang ,China.Welcome to visit our factory at anytime!

Q2: How does your factory do regarding quality control?

A2: Our standard QC system to control quality.

Q3: What is your delivery time?

A3: Usually within 25 days after the receipt of payment.Delivery time must depend on the actual produce condition.

Q4: What are your strengths?

A4: 1.We are the manufacturer,having competitive advantage in price.

2.A large part of money is put into advancing CNC equipments and product

R&D department annual,the performance of cardan shaft can be guaranteed.

3.About quality issues or follow-up after-sales service,we report directly to the boss.

4.We have the ambitions to exploring and developing the world’s cardan shaft market and

we believe we can.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Phasing in Cardan Couplings and Its Impact on Performance

The concept of phasing in cardan couplings refers to the alignment of the universal joints’ yokes or flanges on the input and output shafts. Proper phasing is essential to minimize angular misalignment and maintain smooth rotational motion. When the yokes of the universal joints are not aligned correctly, it can result in uneven torque transmission, increased wear, and vibrations.

Phasing affects the performance of cardan couplings in several ways:

- Uniform Torque Transmission: Proper phasing ensures that torque is evenly distributed between the input and output shafts, reducing the risk of overloading individual universal joints.

- Reduced Vibrations: Correctly phased universal joints minimize angular misalignment, which helps reduce vibrations and noise in the machinery system.

- Extended Lifespan: Improved phasing leads to reduced wear and stress on the universal joint components, extending the overall lifespan of the coupling.

- Efficient Power Transmission: Proper phasing contributes to efficient power transmission by minimizing energy losses due to misalignment.

To achieve proper phasing, manufacturers often provide guidelines or marks on the coupling components to ensure accurate alignment. It’s essential to follow these guidelines during installation and any maintenance or adjustments to maintain optimal performance and reliability of the cardan coupling.

Handling High Torque and Axial Displacement with Cardan Couplings

Cardan couplings, also known as universal joints or u-joints, are designed to transmit torque between two shafts that are not in a straight line. They are versatile components commonly used in various applications, including those requiring high torque and axial displacement.

Handling High Torque: Cardan couplings are capable of handling high levels of torque transmission due to their robust design and construction. The design allows for torque to be transmitted through a series of interconnected components, including the cross-shaped yokes and the bearing assemblies. The use of high-strength materials and precision manufacturing techniques contributes to the coupling’s ability to transmit torque efficiently.

Handling Axial Displacement: While cardan couplings are primarily designed for accommodating angular misalignment, they can also handle a certain degree of axial displacement. Axial displacement refers to the movement of the connected shafts along their axis. However, the axial displacement capacity of a cardan coupling is limited compared to its ability to handle angular misalignment.

It’s important to note that excessive torque or axial displacement beyond the coupling’s design limits can lead to premature wear, increased vibrations, and reduced performance. Manufacturers provide specifications and guidelines for the maximum torque and axial displacement that a specific cardan coupling can handle. Engineers and designers should adhere to these specifications to ensure optimal performance and longevity of the coupling in their applications.

Accommodation of Angular Misalignment in Shaft with Cardan Coupling

A cardan coupling, also known as a universal joint or u-joint, is designed to accommodate angular misalignment between two shafts while maintaining a constant velocity transfer. Here’s how it works:

The cardan coupling consists of two yokes or fork-like components, each attached to the end of a shaft. These yokes are connected by a cross-shaped central component called the cross or spider. The spider has bearings at its four ends that fit into grooves in the yokes.

When the connected shafts are misaligned at an angle, the spider allows the yokes to pivot around their respective shafts. This pivoting action of the yokes and the spider enables the coupling to transmit torque between the shafts even when they are not perfectly aligned. The spider’s bearings allow smooth rotation and transfer of power.

The design of the cardan coupling ensures that even during angular misalignment, the rotational speed remains consistent between the input and output shafts. However, it’s important to note that while cardan couplings can accommodate angular misalignment, they introduce a small amount of radial and axial movement, which can lead to fluctuating torque and vibration.

Cardan couplings are commonly used in applications where there is a need to transmit torque between shafts that are not in line, such as in drivetrains, vehicle suspensions, and industrial machinery.

editor by CX 2024-02-20